By - Jennifer Gilligan, IntegraMSP President

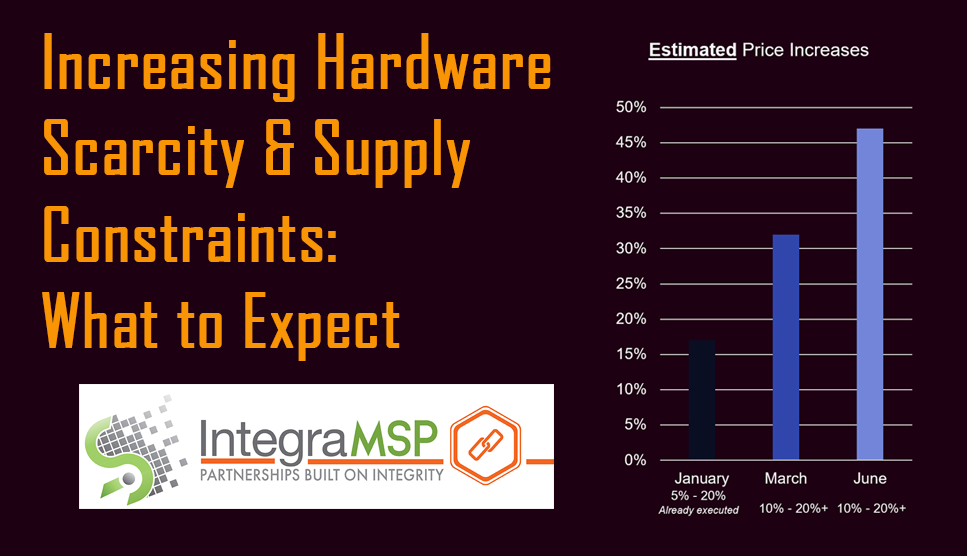

Hardware scarcity is increasing across the technology industry, and it’s no longer theoretical. Availability is tightening, pricing pressure is building, and lead times are becoming less predictable. If you’re responsible for planning technology purchases, the timing of decisions now matters more than it has in years.

This isn’t a single-vendor issue. It’s a broader market shift already underway.

What’s actually driving this

Across the global hardware market, demand continues to rise while supply tightens. Core components—memory, storage, processors—are under sustained pressure as manufacturers redirect capacity toward higher-margin, AI-driven infrastructure.

That shift started showing up in earnest in 2025 and is expected to continue well into 2026. The downstream effect is simple: fewer available configurations, more variability in pricing, and less tolerance for last-minute decisions.

What we’re seeing on the ground

From an operational standpoint, hardware procurement is becoming harder to predict in two key ways:

-

Pricing is less stable.

-

Availability is less reliable.

As a result, quotes increasingly reflect what’s available and priced on the day they’re issued, not what might be available weeks later.

In practical terms, this shows up as:

-

Fewer configuration options for popular devices

-

Longer or shifting lead times

-

Pricing changes between planning, quoting, and ordering

-

Limited replacement options when a specific model goes out of stock

The biggest risk right now isn’t disruption—it’s assuming procurement will continue to work the way it always has.

Why timing is now a cost factor

In a constrained supply environment, timing becomes part of the price.

Organizations that wait until hardware is urgently needed are more likely to face:

-

Higher costs

-

Reduced choice

-

Compromises on specs or delivery timelines

Those that plan earlier retain more control—over budget, configuration, and outcomes.

This isn’t about panic buying, rather it's about acknowledging that the margin for error is smaller than it used to be.

What reduces exposure

What’s helping right now is fairly unglamorous—but effective:

-

Reviewing refresh cycles earlier than usual

-

Staying flexible on configurations where possible

-

Using available inventory strategically

-

Making informed tradeoffs before supply tightens further

Small adjustments made early tend to prevent larger issues later.

The bottom line

Hardware scarcity is increasing. Supply constraints are real. Pricing pressure isn’t going away in the near term.

The organizations that adapt their planning habits—not just their budgets—will have the easiest time navigating what comes next.